Closed-Loop Circularity

Transforming scrap into sustainable infrastructure

Steel is one of the primary materials used in building construction. Ensuring the circularity of this material could significantly reduce the environmental impact of the construction industry. Using tools like CircularPass, the loop for steel has been successfully closed, demonstrating that materials from demolished buildings in the area were repurposed to create new steel-based products used in constructing the Palma Airport terminal. This 100% closed-loop project sets a benchmark for circularity and establishes a foundation for sustainability in the construction sector.

Project Goals

🌍Achieve Closed-Loop Circularity in Steel

🌍Ensure Full Traceability Across the Steel Lifecycle

🌍Promote Collaboration Between Recyclers and Manufacturers

🌍Demonstrate the Environmental Benefits of Circular Construction Practices

Closed-Loop Circularity Key Features

End-to-End Traceability

Tracking of steel across the entire lifecycle, from demolition and recycling to manufacturing, ensuring full visibility and accountability within the supply chain.

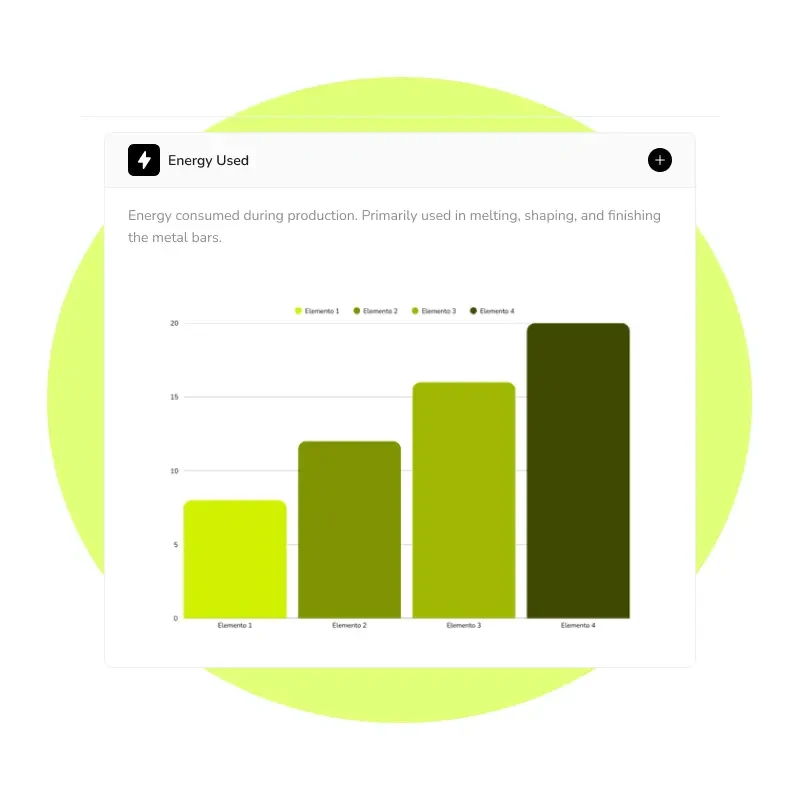

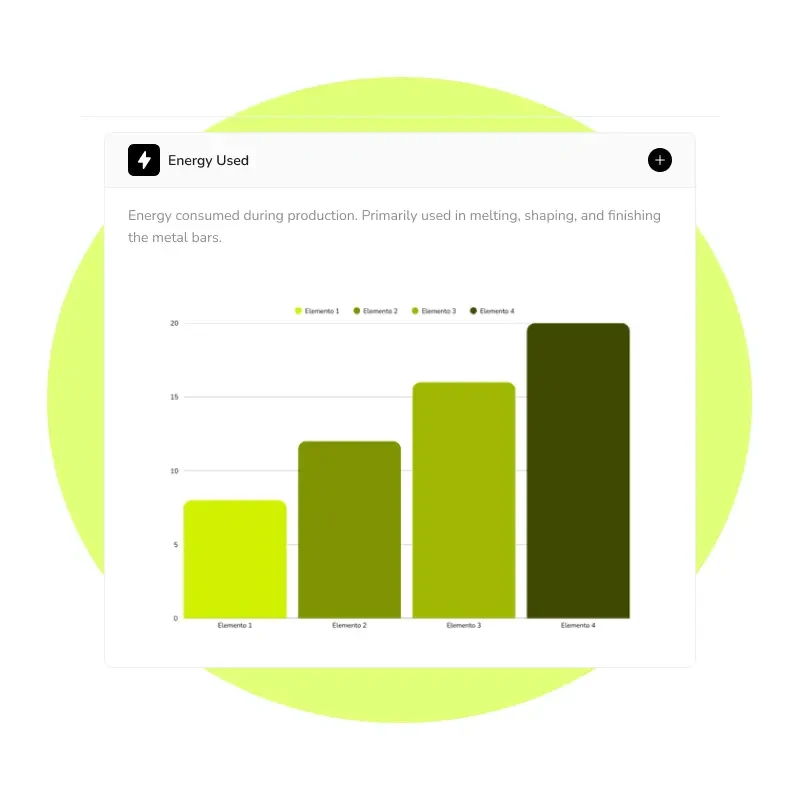

Sustainability Metrics and Environmental Impact Analysis

Enables companies to monitor the origin and movement of materials throughout their lifecycle. This ensures compliance with sustainability standards and enhances transparency in the supply chain.

Seamless Recycler-Manufacturer Integration

Facilitates direct collaboration between recyclers and manufacturers by integrating data from recycling processes into production workflows.

Our Collaboration

Our collaboration with the Palma Airport terminal project highlights the successful implementation of circularity in the construction steel sector. By using CircularPass, we facilitated the repurposing of steel from demolished buildings in the area to create new products for the terminal's construction. The seamless collaboration between Adalmo, the recycler, and Celsa, the manufacturer, ensured that the steel was effectively recycled and transformed into high-quality products.

CircularPass played a pivotal role by providing end-to-end traceability through digital waste and product passports, ensuring the materials’ origin and sustainability were transparent and verifiable. This 100% closed-loop project sets a new standard for sustainability in the construction industry, demonstrating that circular practices in steel are not only feasible but also environmentally advantageous.

The Solution

In this case, CircularPass facilitates collaboration between Adalmo, the recycler, and Celsa, the manufacturer, to ensure that steel recovered from demolished buildings is transformed into new products.

The platform seamlessly integrates data from demolition, recycling, and manufacturing processes, effectively closing the material loop. By linking digital waste passports to product passports, CircularPass provides a transparent and verifiable chain of custody, certifying the origin and sustainability of the recycled steel.

Discover more Use Cases

Circular Steel Traceability

Transparent Lifecycle for Automotive Products

CircularPort

Extending traceability of port beyond the port for greener & circular ports

Closed Loop Circularity

Transforming scrap into sustainable infrastructure

Start Your Journey to Supply Chain Transparency Today

Start Your Journey to Supply Chain Transparency Today